Description

A cutting disc, also known as a cutting wheel or cutoff wheel, is a specialized tool used for cutting various materials with precision and efficiency. It is commonly used in industries such as metalworking, construction, automotive, and fabrication. Here are some key characteristics and information about cutting discs:

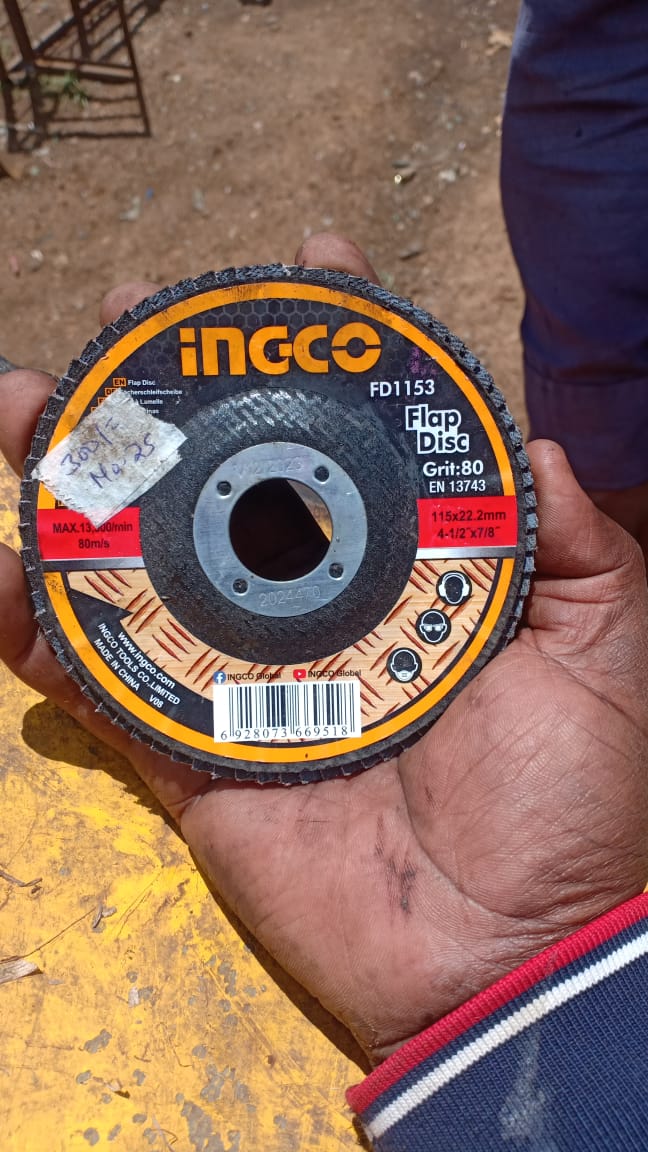

Composition: Cutting discs are typically made of abrasive materials, such as aluminum oxide or silicon carbide, bonded together with a resin or ceramic material. These abrasives are chosen for their hardness, durability, and cutting effectiveness.

Shape and Size: Cutting discs are circular in shape and come in various diameters, ranging from small discs for handheld tools to larger discs for use with stationary cutting machines. The size of the cutting disc depends on the application and the type of tool it is intended for.

Thickness: Cutting discs have different thicknesses, often referred to as the disc’s “thickness” or “width.” Thinner discs are generally used for finer, precision cuts, while thicker discs are used for heavier-duty cutting tasks.

Arbor Hole: Cutting discs feature a central arbor hole in the middle that fits onto the spindle or shaft of the cutting tool. The arbor hole size varies depending on the specific tool the cutting disc is intended for.

Cutting Efficiency: Cutting discs are designed to deliver fast and precise cuts through various materials. They are highly efficient at removing material and creating clean, smooth cuts. The specific cutting efficiency depends on the type and composition of the disc, as well as the speed and power of the tool being used.

Compatibility: Cutting discs are designed for use with specific power tools, such as angle grinders, chop saws, or circular saws. It is important to ensure that the cutting disc being used is compatible with the tool being utilized. This includes matching the disc’s diameter, arbor hole size, and the maximum RPM (Revolutions Per Minute) rating specified for both the disc and the tool.

Safety Considerations: When using cutting discs, it is crucial to follow safety precautions. These include wearing appropriate personal protective equipment (PPE) such as safety glasses, gloves, and hearing protection. It is also essential to read and adhere to the manufacturer’s instructions and recommendations for safe usage.

Application: Cutting discs can be used to cut a wide range of materials, including metals (such as steel, aluminum, or stainless steel), concrete, stone, ceramics, plastics, and more. Different types of cutting discs are available for specific materials and cutting requirements. It’s important to select the appropriate disc for the material being cut to achieve optimal results and ensure safety.

It is worth noting that cutting discs may wear down over time and with use, so it is necessary to regularly inspect them for signs of damage or wear and replace them when necessary to maintain safe and effective cutting performance.

Reviews

There are no reviews yet.